- Work Hours : Mon to Sat : 09:30- 18:30

3D PRINTING PACKAGE FOR P&O DEVICES

Advanced Technologies To Establish A Digital Fabrication Facility

OVERVIEW

At Graft3D Healthcare, we offer hospitals a comprehensive solution that enables the fabrication of personalized P&O devices for their patients. With our package, hospitals can conduct precise body scans of their patients, utilizing the body scans as references to design a wide range of P&O devices that cater to the specific needs of each individual. Our streamlined process ensures efficient mass volume fabrication, guaranteeing that patients receive top-notch, customized solutions of the highest quality.

Workflow and Product Portfolio

3D SCANNING

Utilizing the Einscan-H 3D scanner, medical professionals can accurately capture the geometry and texture of body parts, including the face, hair, amputated limbs, and existing prosthetic and orthopaedic devices.

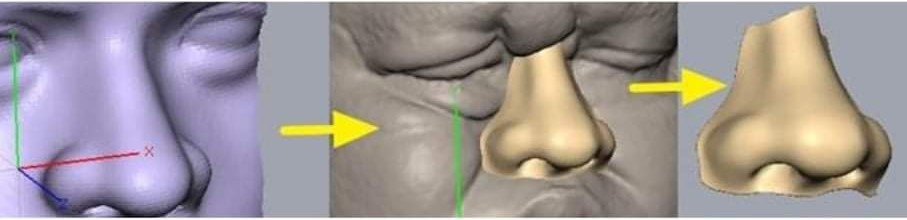

Custom Design

Utilize the Geomagic Freeform CAD system with a haptic touch device to create the patient-specific P&O Devices.

3D Print

Ensure quality control with Geomagic CX software, comparing 3D printed devices to the original design.

Products Bundles

Einscan-Human Body 3D Scanner

- 3D Scan human body parts with Eye-safe & Human skin friendly Hybrid LED & Infrared Light Source Handheld Color 3D Scanner.

- The built-in color camera supports capturing full-color texture and skin tone.

- Scan P&O Devices to compare with the original CAD design.

Geomagic Freeform Software with Haptic Touch Device- Prosthetic & Orthotic Device Design Software

- 3D Scan human body parts with Eye-safe & Human skin friendly Hybrid LED & Infrared Light Source Handheld Color 3D Scanner.

- The built-in color camera supports capturing full-color texture and skin tone.

- Scan P&O Devices to compare with the original CAD design.

EXT 1070 Tital Pellet LT* (ATLAS 2.5)-Prosthetic 3D Printer

- 3D Print P&O devices with PEBA flexible nylon pellets and mineral-filled polypropylene pellets.

- Produce up to 200 to 300 devices in a month.

- Fast printing for multiple iterations and customization.

- Test the fit and customize further for optimized design for best fit and performance.

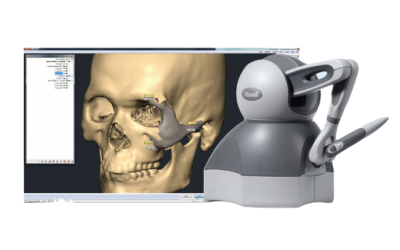

Geomagic CX: Quality Control & Inspection of Medical Devices:

- 3D inspect the final P&O devices after production.

- Precisely measure, analyze, and verify critical dimensions and geometries.

- Report & document the result of a patient's medical condition, before and after surgery, and the inspection results of the devices.

Benefits Of Setting up In-house Digital Manufacturing of P&O Devices

- For the Hospital

- For the Patients

-

Provide personalized P&O devices, tailored to each patient's unique needs, resulting in improved patient comfort, functionality, and overall satisfaction.

-

Eliminate the need for outsourcing, reduce lead times, and provide faster and more efficient services to patients.

-

Eliminate costs associated with traditional manufacturing methods, such as casting, molding, and manual fabrication.

-

Maintain control over the production process, ensuring quality standards and compliance with regulations.

-

3D Printed P&O devices printed are highly personalized fit and designed.

-

Devices are designed with Reduced pressure points, for increased comfort.

-

Improved mobility and Lightweight to reduce fatigue to use it for a long time.

-

Get the device in shorter lead times with Faster production of P&O devices.

FAQs

A 3D printing lab for prosthetic and orthotic devices is a specialized facility for hospitals and educational institutions that utilizes 3D scans, medical 3D design and 3D printing technology to create customized and personalized prosthetics and orthotics for patients with specific needs.

Hospitals can have the ability to design P&O devices that are custom-made for each patient, perfectly suiting their individual needs. This not only reduces the time but also ensures faster and more efficient service for our valued patients. Moreover, by adopting advanced 3D printing technology, we can cut down on expenses linked to traditional manufacturing techniques like casting, moulding, and manual fabrication, making it cost-effective and accessible to all.

Our 3D printing lab can produce a wide range of prosthetic and orthotic devices, such as Prosthetic sockets for amputees, Custom orthotic insoles for foot support and correction, Ankle-foot orthoses (AFOs) for gait improvement, Knee orthoses for stability and support, Upper limb prosthetics for arm amputees.

Our 3D printing lab utilizes advanced pellet extrusion 3D printing to enable fast prnting P&O devices.

3D printed devices that are printed in our lab are designed and printed based on the patient’s 3D scan so we will ensure the highest level of accuracy that fits the patient’s body parts.

Yes, our 3D-printed prosthetic and orthotic devices are designed to be durable and long-lasting. We use high-quality materials and follow industry best practices to ensure that the devices can withstand daily wear and tear, providing lasting support and comfort to patients.

To get started with setting up a 3D printing lab for prosthetic and orthotic devices, hospitals can reach out to our team at [email protected], We offer comprehensive consulting and support services, guiding hospitals through the entire process, from selecting the right 3D printing technologies to training staff and implementing the lab.

Download 3D Printing Package Devices Brochure

Book A Demo

- PHOTOS

- VIDEOS

Our Blogs