- Work Hours : Mon to Sat : 09:30- 18:30

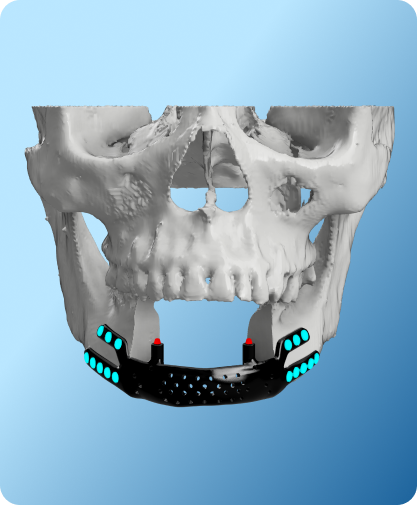

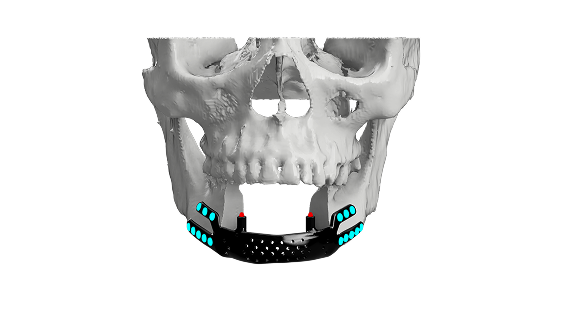

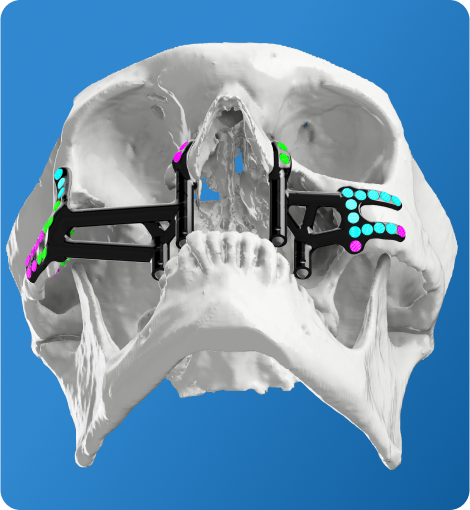

Reconstruction of Resected Mandible and Maxilla

- Designed by Zoriox Innovation Labs ,Marketed by Graft3D Healthcare Solutions

Overview

Reconstruction of the mandible and maxilla is one of the most challenging areas in oral and maxillofacial surgery. It is often necessary following resection for cancers, benign lesions, mucormycosis or severe trauma. These defects need to be addressed for skeletal continuity, and also for correction of occlusion, mastication, speech and facial aesthetics.

Conventional reconstruction methods are associated with the drawbacks of donor site morbidity, unsatisfactory anatomical correspondence and longer operation time. The advent of 3D-printed patient-specific implants (PSIs) has transformed craniofacial reconstruction. By incorporating digital surgical planning, advanced imaging and biomechanical optimization with finite element analysis (FEA), these implants provide an accurate anatomical restoration and functional rehabilitation.

Design Workflow for 3D-

Printed Implants

Imaging and Virtual Planning

The basis of virtual surgical planning is the high-resolution CT scan. Defective areas are outlined and 3D models with details of the defect are prepared to be used for preoperative planning. This yields valuable information for planning reconstruction of mandibular defects and maxillary defects treatment.

Imaging and Virtual Planning

The basis of virtual surgical planning is the high-resolution CT scan. Defective areas are outlined and 3D models with details of the defect are prepared to be used for preoperative planning. This yields valuable information for planning reconstruction of mandibular defects and maxillary defects treatment.

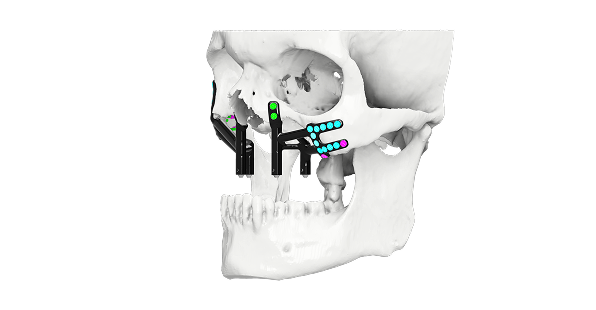

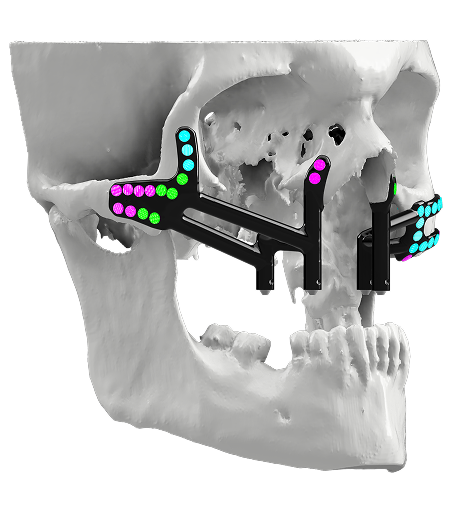

Reconstruction of Single-Sided Defects

For mandibular and maxillary resections, the unaffected side is digitally mirrored. This guarantees an ideal anatomical fit and provides for normal facial balance in mandibular reconstruction and maxillary reconstruction cases.

Base Plate and Fixation Design

A baseplate is then custom designed to fit the residual bone. Trajectory screws are well planed, without any passage to critical structures like canals or dental roots in order to ensure safety and stability.

Biomechanical Optimization

Finite element analysis is performed before final fabrication for the evaluation of stresses and strains in the implant. Load bearing areas such as the mandibular angle, parasymphysis and condylar regions are provided with added strength. This mechanism guarantees biomechanical dependability for activities of mastication and speech, critical in trauma-related mandibular resection with the use of PSIs.

Clinical Applications of Patient-Specific Implants

Oncological Resection

For oral tumors and cancers, oncologic mandibular reconstruction with PSIs permits post-resection rehabilitation immediately. The prosthesis restores continuity of bone,supports the maxilla and orbital floor, reestablishing physiological as well as cosmetic function.

Infective Pathologies

There has been an increase in mucormycosis affected jaw reconstruction cases using 3D printing post-COVID-19. Patient-specific implants offer precise solutions for large defects, particularly in patients with high surgical risk of free flap surgery.

Trauma Reconstruction

Patient specific implants are used to fix complex maxillary and mandibular fractures and control bone loss. They re-establish occlusion, preserve facial balance and proportions without adding to intra-operative time.

Advantages of 3D-Printed Patient-Specific Implants

Anatomical Precision:

Precise fit through digital surgical planning and virtual mirroring.

Time Efficiency:

Prefabricated implants reduce surgical time compared to traditional methods.

Biomechanical Strength:

Finite element analysis in implants ensures long-term durability and

resistance to functional stresses.

Enhanced Functional and Aesthetic Outcomes:

Improved mastication, speech, and facial aesthetics.

Reduced Morbidity:

Avoids donor site complications of free flap surgery, making it ideal for

customized maxilla and mandible implants.

The application of 3D-printing using patient-specific implants in mandible and maxilla reconstruction represents a turn-around in craniofacial reconstruction. The integration of 3D printing, virtual surgical planning and biomechanical optimization of implants enable accurate anatomical restoration, functional rehabilitation, and excellent cosmetic results. 3D-printed patient specific implants restore the exact anatomy of maxilla and mandible and also improves the confidence and long-term oral health of patients.

1) What does reconstruction of resected mandible and maxilla involve?

Reconstruction of resected mandible and maxilla involves rebuilding jaw segments removed due to trauma, tumours, or disease. It restores chewing, speech, and facial structure using bone grafts or custom implants tailored to patient anatomy.

2) Why are mandible and maxilla reconstruction services important for hospitals?

Mandible and maxilla reconstruction services provide clinical teams with comprehensive planning, design, and fixation solutions. These services improve alignment, reduce surgery time, and help achieve better functional and aesthetic outcomes for complex defects.

3) What are 3D printed jaw reconstruction implants?

3D printed jaw reconstruction implants are custom devices made using additive manufacturing. They match patient anatomy precisely, support strong fixation, and can be planned alongside surgical rehearsal to enhance predictability and fit.

4) What makes patient-specific mandibular and maxillary implants different?

Patient-specific mandibular and maxillary implants are created from individual CT/CBCT scans. Their customized geometry provides a closer anatomical match than standard implants, reducing intraoperative adjustment and improving long-term stability.

5) How do custom 3D printed mandibular implants support surgical outcomes?

Custom 3D printed mandibular implants are designed to mirror the jaw’s unique curvature and load-bearing needs. This precise fit helps surgeons reduce operating time and improve functional restoration for chewing and speech.

6) Where are custom 3D printed maxillary implants used most often?

Custom 3D printed maxillary implants are often used when the upper jaw needs reconstruction after trauma or tumour resection. Designed from patient imaging, they help rebuild support for the midface and dental occlusion.

7) What is mandible resection reconstruction and when is it needed?

Mandible resection reconstruction refers to rebuilding the lower jaw after part of it has been surgically removed. It’s needed to restore continuity, oral function, and facial symmetry following tumour surgery or severe injury.

8) How do 3D printed jaw reconstruction implants for surgeons improve planning?

3D printed jaw reconstruction implants for surgeons allow pre-surgical design and simulation using patient imaging. This supports precise implant positioning, reduces guesswork during surgery, and enhances confidence for complex reconstructive steps.

9) What defines hospital-grade mandibular and maxillary implant services?

Hospital-grade mandibular and maxillary implant services offer end-to-end workflows from imaging to custom implant delivery, with quality checks, documentation, and compatibility with clinical sterilization practices required for safe surgical use.

10) Can custom implants reduce recovery time after jaw reconstruction?

Yes — custom implants tailored to individual anatomy can improve fit, reduce intraoperative adjustments, and support more accurate fixation. This often contributes to smoother rehabilitation and faster return to oral function than non-custom alternatives.

Contact Us & Get details for