- Work Hours : Mon to Sat : 09:30- 18:30

3D Printing in Cranial Vault Reconstruction

- Designed by Zoriox Innovation Labs ,Marketed by Graft3D Healthcare Solutions

Overview

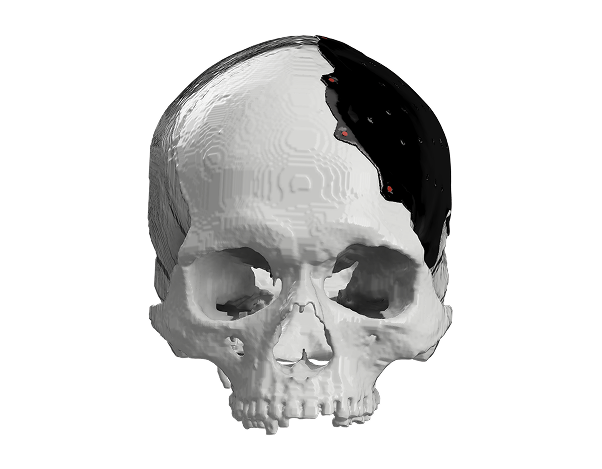

Cranial vault reconstruction is a complicated procedure that aims to

reconstruct the cranium after injury, tumor resection, congenital

malformation, or infection to re-establish its integrity, shape and protective

quality. The use of traditional plates or mesh for reconstruction often

requires intraoperative adjustment, which prolongs operative time and can

negatively impact functional and aesthetic results. 3D printing and patient

specific implants (PSIs) have revolutionized cranial reconstruction, making

it an accurate technique with good aesthetic outcomes.

Indications for 3D-Printed Cranial Reconstruction

- Post-traumatic cranial defects: Post Traumatic Brain Injury or decompressive craniectomy.

- Oncologic reconstruction: Post Tumor resection such as meningiomas or osteosarcomas.

- Congenital skull defects: Applicable in craniosynostosis and other developmental problems.

- Post infective cranial defects: Following osteomyelitis or bone loss through infection.

- Cosmetic and functional rehabilitation: To re-establish natural cranial anatomy to protect the intracranial structures.

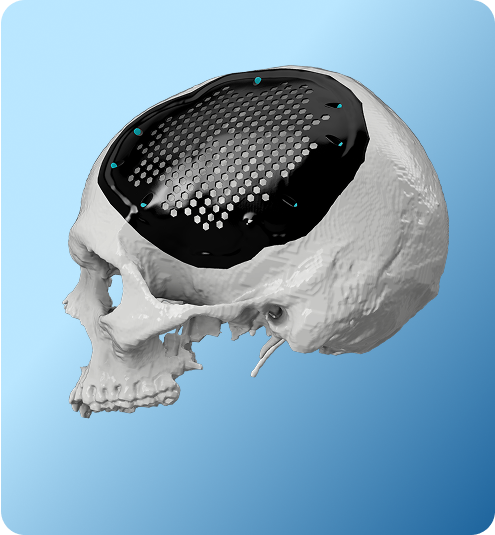

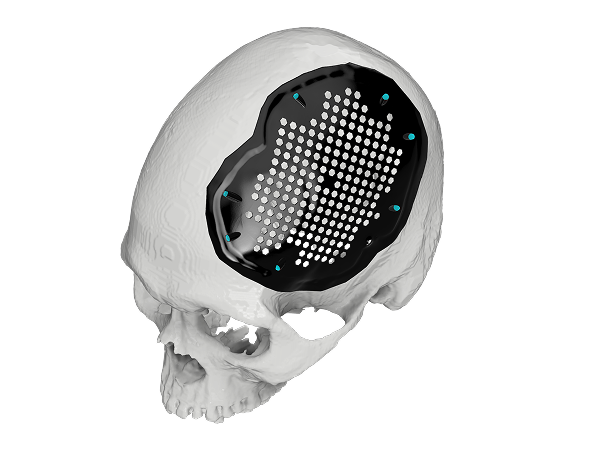

The Role of 3D Printing in Cranioplasty

- High resolution CT scans are used to generate smooth 3D printed models of the patient's cranial defect.

- A 3D model of the cranium could be generated by computer aided design (CAD) software, and patient specific cranial implant through virtual reconstruction and additive manufacturing.

- These patient customized cranial implants are manufactured to correct the defect size, shape and curvature resulting in optimized anatomical match, better protection of neural elements and aesthetic outcomes.

Benefits of 3D Printed Patient Specific Implants

- Precise Fit: Custom made implants eliminate the need for intraoperative adjustments.

- Shorter Operative Time: Pre contoured implants streamline the surgical procedure.

- Enhanced Aesthetics: Achieving better symmetry and anatomy of the cranium.

- Biocompatible: The use of integrated, tissue-friendly materials like titanium and PEEK.

- Predictability: Preoperative preparation and virtual reality computer simulation aid in precision of surgical outcomes.

Materials in 3D Printing Orbital Implants

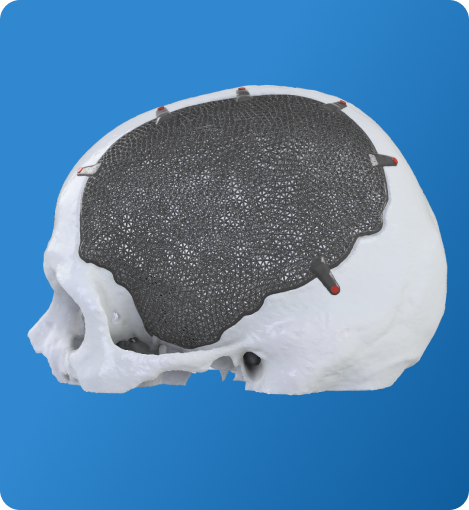

Titanium Implants

- Titanium has high mechanical strength and biocompatibility.

- Fabrication of porous designs, which encourage osseointegration, can be produced by additive manufacturing (e.g. selective laser melting).

- It is well fitted for large, load bearing cranial vault defects.

- Minimal artifact shadows in the CT/MRI scans.

- Limitations: Possible cosmetic issues related to implant palpability and modified thermal conductivity.

Polyetheretherketone (PEEK) Implants

- PEEK exhibits high performance thermoplasticity with bone-like elasticity.

- Lightweight and provides excellent cosmetic enhancement of the cranial vault.

- Metal artifacts are not seen in CT/MRI.

- Used for cosmetic replacement in non-load bearing cranial defects.

- Limitations: Higher cost and slightly inferior osseointegration over porous titanium.

Future Perspectives in 3D-Printed Cranial Reconstruction

- Development of bioresorbable implants for pediatric patients to accommodate cranial growth.

- Hybrid implant designs integrating titanium for structural strength and PEEK for aesthetic optimization.

- Application of AI assisted design algorithms to improve precision and predictability.

- Progress in bioprinting of bone scaffolds with stem cells, enabling regenerative approaches to cranial vault reconstruction.

The integration of 3D printing in the cranial vault reconstruction has revolutionized the treatment of challenging cranioplasty cases. 3D-printed cranial implants enable decreased operative time and better cosmetic and functional results, when compared to conventional reconstruction techniques. Materials such as titanium and PEEK are versatile, strong and biocompatible and used in different clinical indications. With progress in AI design, hybrid implants and bioprinting technologies the future of personalized cranial reconstruction is on the verge of transitioning from structural restoration to actual regenerative solutions.

FAQs

What is cranial vault reconstruction and when is it clinically indicated?

Cranial vault reconstruction is performed to restore skull defects caused by trauma, tumour resection, infection, or decompressive craniectomy. The procedure protects intracranial structures and restores anatomical contour and symmetry.

How does medical 3D printing support cranial vault reconstruction?

Medical 3D printing for cranial vault reconstruction enables the creation of accurate 3D printed cranial bone models and patient-specific cranial implants, allowing surgeons to plan defect coverage, fixation strategy, and implant thickness preoperatively.

When are PMMA implants used in cranial defect reconstruction?

PMMA is commonly used for cranial defect reconstruction due to its long clinical history, ease of intraoperative handling, and cost-effectiveness. It is suitable for cases where intraoperative contouring or rapid fabrication is preferred.

What are the clinical advantages of PEEK implants in cranial reconstruction?

PEEK implants offer excellent biocompatibility, radiolucency, and an elastic modulus closer to bone. Patient-specific PEEK cranial implants provide precise fit, improved cosmetic outcomes, and reduced intraoperative adjustments.

How do titanium cranial implants compare with PMMA and PEEK?

Titanium cranial implants provide high mechanical strength and long-term durability, making them suitable for large or complex defects. The choice between titanium, PMMA, and PEEK depends on defect size, location, soft-tissue condition, and surgeon preference.

What should hospitals look for in 3D printed cranial prosthesis solutions?

Hospitals should choose cranial defect reconstruction providers that offer validated design workflows, custom 3D cranial implants for hospitals, multiple material options (PMMA, PEEK, titanium), and regulatory-compliant 3D printed cranial prosthesis solutions