- Work Hours : Mon to Sat : 09:30- 18:30

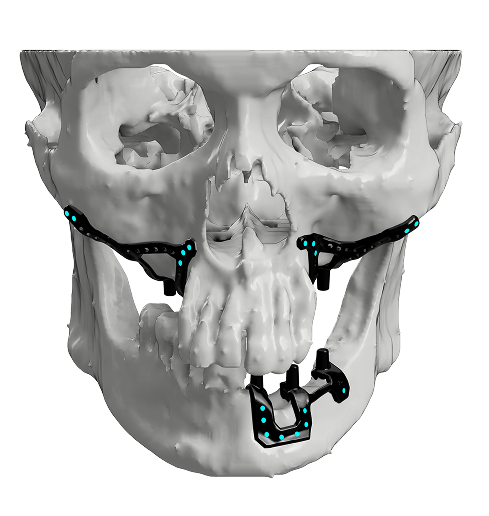

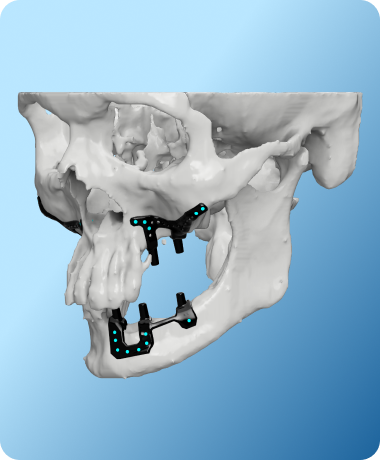

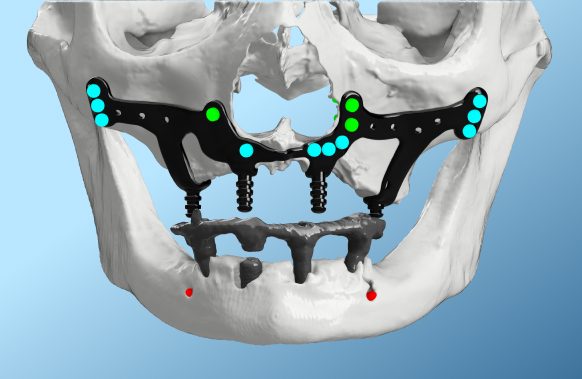

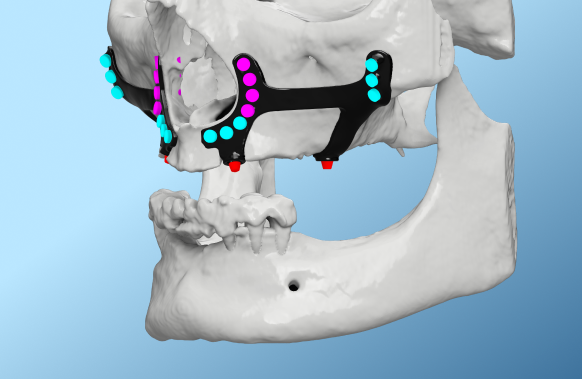

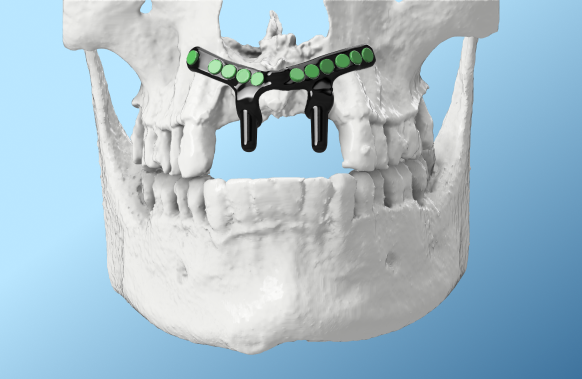

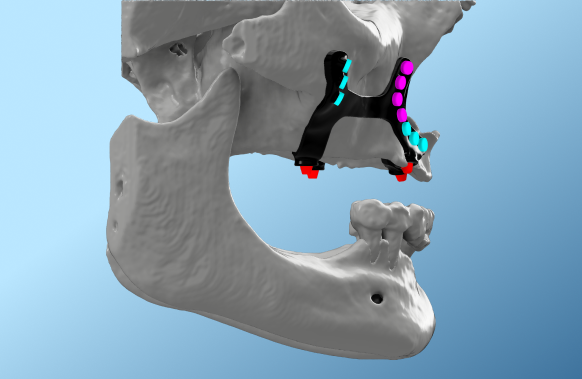

Patient Specific Implants For Atrophic Maxilla and Mandible

Overview

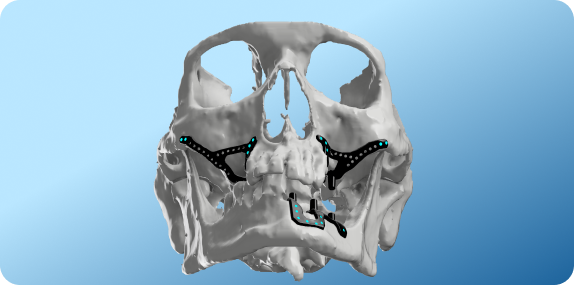

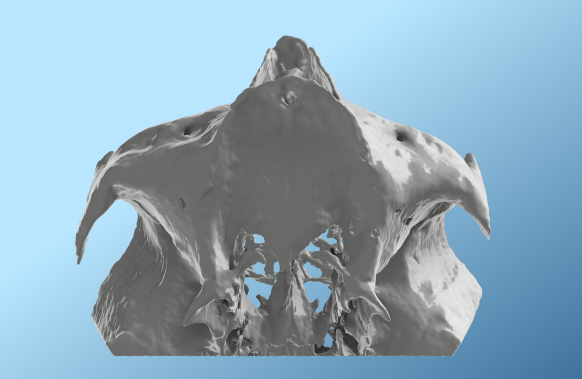

Restoration of the anatomical and morphological function in the maxilla and mandible can be complicated, in cases of severe bone resorption. In such cases, traditional reconstruction methods do not work well, requiring extensive adjustments during surgery, increasing surgical time, and resulting in less predictable outcomes. Recently, patient-specific implants (PSIs) have become a benchmark solution for resection of maxilla and mandible by harnessing cutting edge digital planning and advanced manufacturing.

Digital and Manufacturing

Technologies Used

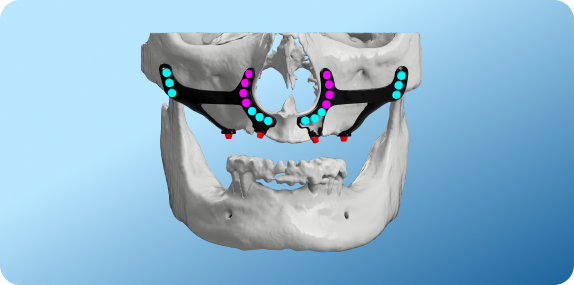

- Preoperative Planning Tools: Advanced imaging (CT) and digital implant planning software are used for anatomical assessment and surgical simulation.

- 3D Printing Devices: Used to produce patient specific guides and implants based on digital designs from anatomical segmentation.

- CAD/CAM Software: Computer-aided design and manufacturing platforms for implant customization and guide fabrication.

Armamentarium for Patient Specific Implants

- Surgical & Osteotomy Instruments: Includes scalpels, periosteal elevators, retractors, osteotomes, piezosurgery units, saws, burs, and bone files required to access, mobilize, and shape the maxilla or mandible safely.

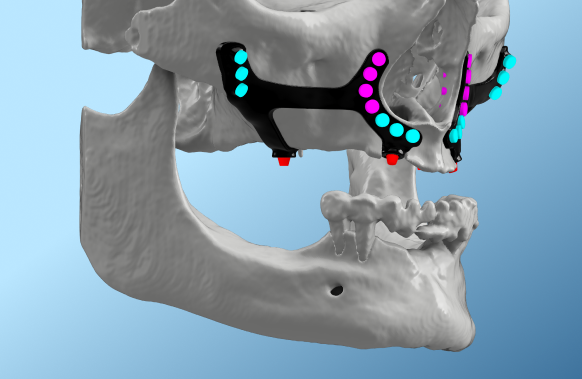

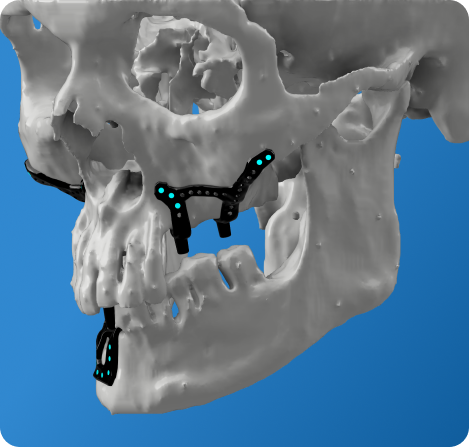

- PSI Placement & Fixation Tools: Custom cutting/drilling guides, patient-specific plates or meshes, drills with depth control, torque-limiting drivers, and a range of monocortical and bicortical screws for rigid fixation.

Advantages of PSIs Over Traditional Methods

Exceptional Accuracy

PSIs enable precise transfer of the virtual surgical plan to the patient, achieving minimal deviations as low as 0.3 mm in vertical/transverse dimensions and 0.7 mm anteroposteriorly.

Surgical Efficiency

3D Implant designs and cutting guides streamline the intraoperative process, reducing operative time and complexity.

Increased Fixation

Rigidity & Stability

Custom titanium plates are thicker and better adapted to optimal bone areas, offering stronger biomechanical resistance.

Enhanced Functional

and Aesthetic Outcomes

Patient specific implants enhance speech clarity and swallowing function by providing proper support for phonation and deglutition needs. It ensures that the maxillofacial skeleton is positioned correctly, improving patient satisfaction.

Better Adaptation in

Defect Reconstruction

The implant designs can be customized for individuals who have undergone tumor removal, radiation therapy, or sustained tissue scarring, enabling highly accurate fitting with improved cosmetic and functional outcomes.

Reduced Donor Site Morbidity

Patient specific implants eliminate the need for tissue grafts or free flap procedures, thereby minimizing the risk of complications at donor sites and improving overall patient outcomes.

Possible Complications

- Common complication, post treatment includes soft tissue inflammation around the implants leading to bone loss.

- Other complications include hygiene problems, bleeding, infection and delayed wound healing.

- High masticatory load can reduce the durability of the implants.

FAQs

What are patient-specific implants (PSIs) for atrophic maxilla and mandible?

Patient-specific implants are custom-designed subperiosteal or framework implants created from CBCT/CT-based virtual planning to restore severely resorbed maxillary or mandibular bone where conventional endosseous implants are not feasible.

In which clinical situations are PSIs preferred over bone grafting or zygomatic implants?

PSIs are ideal in cases of advanced ridge atrophy, failed grafts, compromised anatomy, or patients unsuitable for multi-stage grafting procedures, offering a single-stage, graft-less solution with immediate functional stability.

How does virtual surgical planning improve accuracy and outcomes?

Virtual surgical planning enables precise adaptation of the implant to the patient’s residual bone anatomy, optimized fixation point placement, and prosthetic-driven positioning—resulting in high surgical predictability and reduced intraoperative adjustments.

Do patient-specific implants reduce surgical time and morbidity?

Yes. Pre-planned, custom-fit implants significantly reduce operative time, eliminate extensive bone augmentation procedures, and minimize patient morbidity, leading to faster recovery and fewer surgical stages.

How is long-term stability achieved in severely atrophic cases?

Stability is achieved through multi-point cortical fixation, load distribution over a wider anatomical area, and precise implant-bone adaptation—ensuring reliable long-term support for prosthetic rehabilitation.

Can PSIs support immediate or early prosthetic loading?

Yes. In appropriately planned cases, PSIs can support immediate or early prosthetic loading, allowing faster functional and aesthetic rehabilitation while maintaining biomechanical stability.