- Work Hours : Mon to Sat : 09:30- 18:30

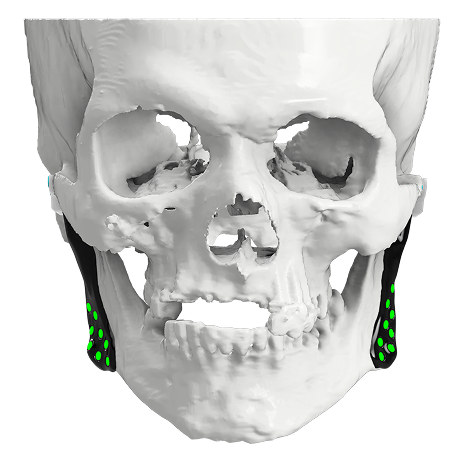

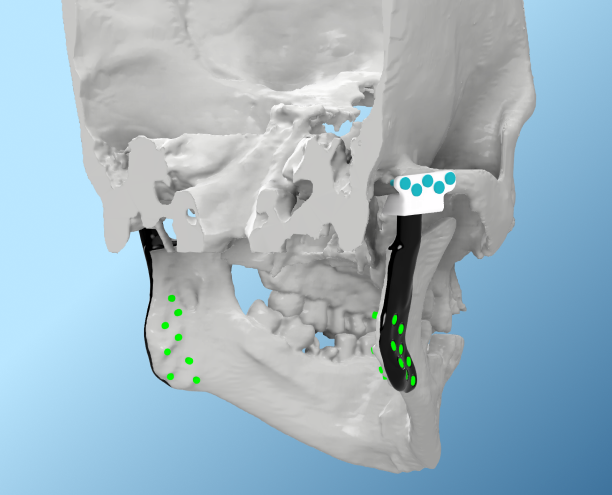

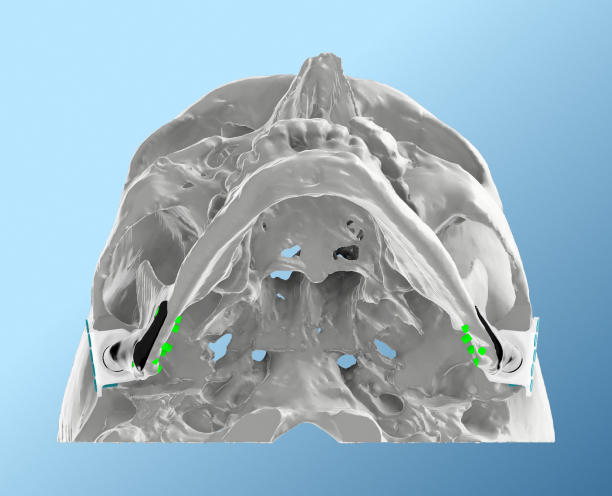

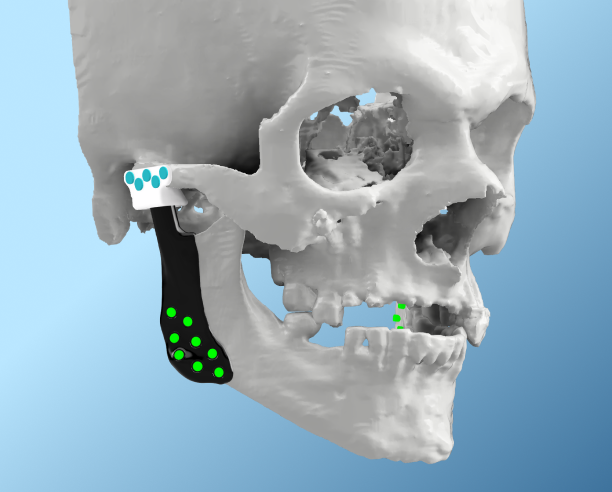

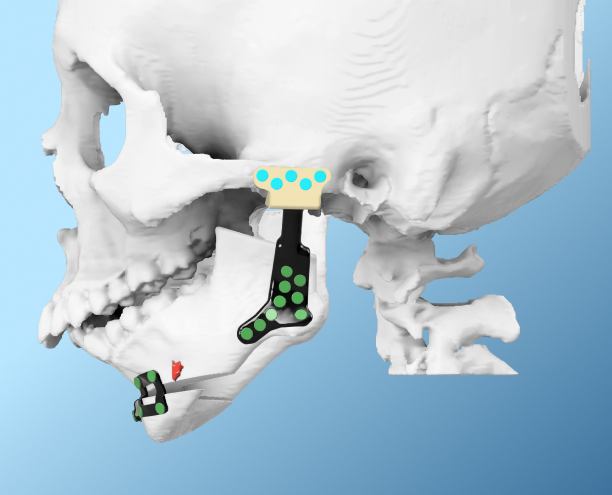

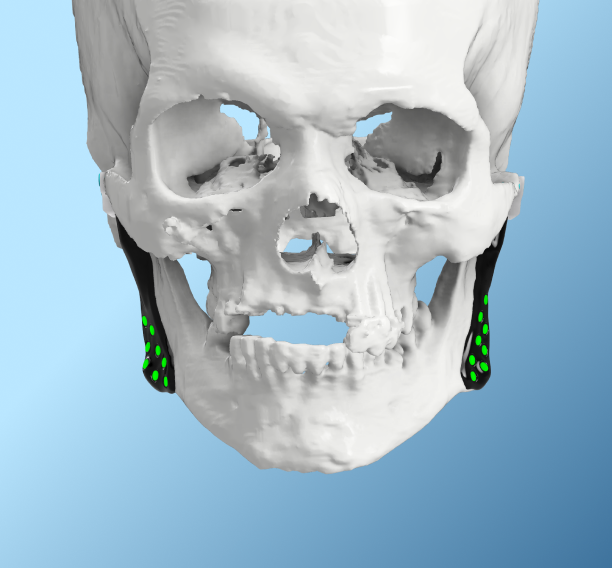

Temporomandibular Joint (TMJ) Replacement with 3D-Printed Titanium Implants

- Designed by Zoriox Innovation Labs ,Marketed by Graft3D Healthcare Solutions

Overview

Temporomandibular joint replacement (TJR) is a surgical treatment to restore function and alleviate pain in patients with a chronically deranged TMJ. It is indicated in cases of bony ankylosis, failed autogenous grafting, destructive tumours, post traumatic deformities, or degenerative arthritis of the temporomandibular joint. Traditional methods of reconstruction, like costochondral grafting, are frequently associated with donor site morbidity, resorption and unpredictable long term results.

Advanced digital technology and additive manufacturing have further paved the way for the era of 3D-printed personalized TMJ prosthesis. These custom made implants provide more accurate anatomical fit, superior functionality, and improved patient satisfaction when compared to traditional, stock type prosthetic systems.

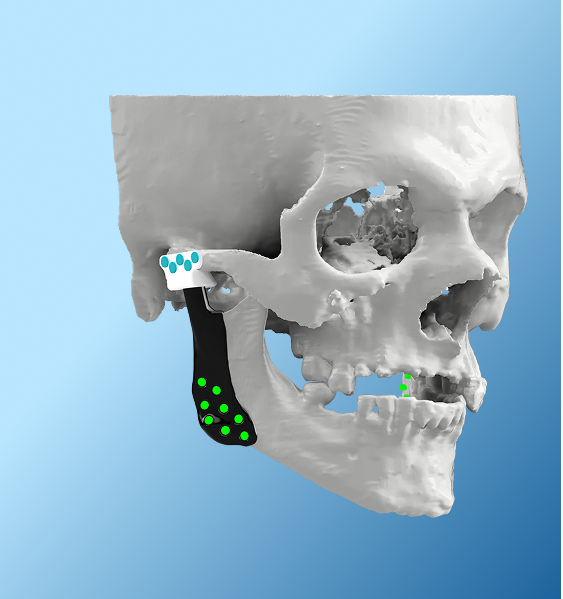

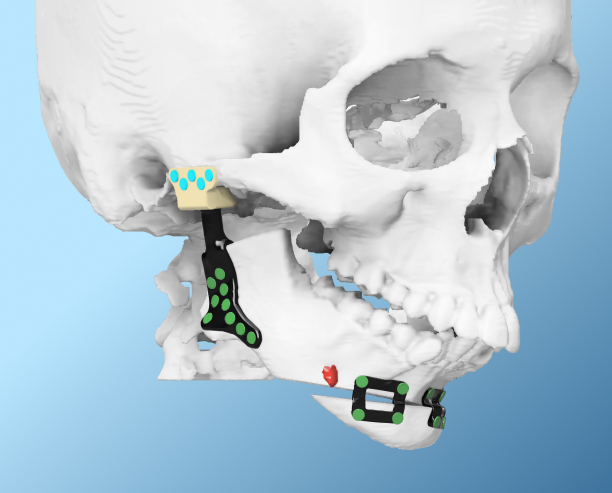

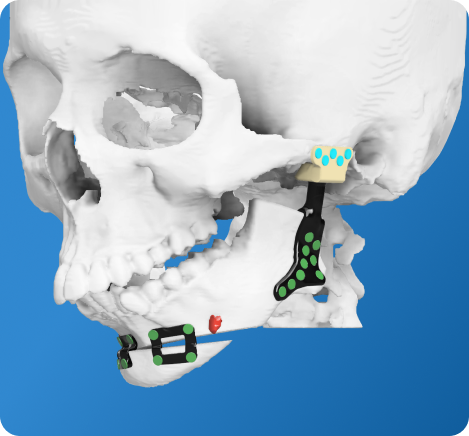

The modern TMJ prosthesis is composed of two primary components

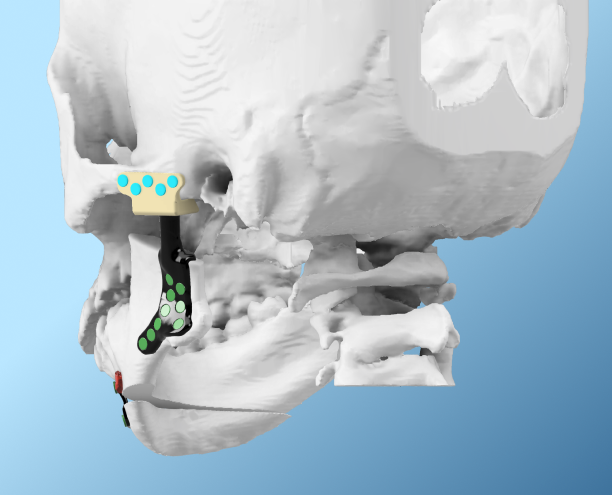

- Condylar Component: It is made of titanium alloy (Ti-6Al-4V) through high-precision additive manufacturing, possessing superior biocompatibility, good load bearing capacity, customized to the anatomy of the patient.

- Glenoid Fossa Component: Fabricated from Ultra High Molecular Weight Polyethylene (UHMWPE), it is designed to mimic the gliding interface of the human joint, facilitating smooth and effective biomechanics while improving longevity.

Advantages of 3D Printed Titanium TMJ Prosthesis

Patient-Specific Design

- Advanced imaging, such as CT scans and digital surgical planning, makes it possible to develop implants that mirror the exact anatomy of the patient.

- This helps to reestablish the joint anatomy, position and occlusion with optimized aesthetic and functional results.

Material Advantages

Titanium Condylar Component

- Lightweight, but tough enough to be functional load bearing.

- Exhibits osseointegration, non-corrosive and biocompatible that maintains years of service.

- Safe for patients who may further undergo other imaging studies, such as MRI.

UHMWPE Glenoid Component

- Offers a wear-resistant, smooth surface for articulation, replicating the original joint.

- Reduces friction and wear particle generation, reducing the chance of implant failure.

- Reduces stress transmitted to the adjacent bone, minimizing bone resorption and extending the life of the prosthesis.

Functional Outcomes

- Patients exhibit a degree of immediate improvement in mandibular mobility with increased mouth opening and decreased pain.

- Rehabilitation of mastication and speech is effectively achieved.

- A stable occlusion and an enduring joint function are achieved with minimal complications.

Surgical Advantages

- Pre operative digital planning minimizes the duration of the surgery, minimizes intraoperative trial and error, and results in predictable outcomes.

- Customized implants avoid autogenous graft harvesting and potential donor site morbidity.

- TMJ replacement can be combined with orthognathic surgery, to optimize the final results.

Longevity and Safety

- Clinical findings show survival rates of >85–90% at long-term follow-up, supporting the safety and quality of the patient specific prostheses.

- They are best suited for adult patients because risk of growth related resorption is minimal as compared to biologic grafts.

- Long term patient satisfaction is favorable as a result of pain reduction and functional recovery.

Unilateral TMJ Replacement

- Favored treatment in cases where only one joint is involved, like localized ankyloses, trauma or tumor resection.

- The adjacent joint remains biologically intact, allowing normal motion and proprioception.

- Necessary consideration of occlusal balance and mandibular function to address symmetry

- Provides shortened operation time and reduced morbidity.

Bilateral TMJ Replacement

- Recommended when both joints are involved, like severe degenerative arthritis, bilateral ankylosis, or in cases of multiple failed reconstructions.

- Simultaneous reconstruction of both joints maintains equilibrium in mandibular length, occlusion, and mastication, and contributes to balanced activity in the masticatory system.

- Can be very successful for those with mandibular hypoplasia or micrognathia, often resulting in improved aesthetics.

- Offers predictable long term results when both condyles need to be reconstructed.

Three-dimensional printed, patient-specific TMJ prostheses combining titanium alloy condylar components with UHMWPE fossa counterparts have emerged as the gold standard in temporomandibular joint replacement. The technology based and problem solving approach has allowed customized implants to provide the foundation for robust biomechanical support, personalized anatomical restoration and long term function. In the treatment of single sided and double sided joint pathologies they offer a proven operative therapy with long term improvement of oral function, mandibular symmetry and quality of life.

FAQs

What is ReGraft™ TMJ and what clinical problem does it address?

ReGraft™ TMJ is a patient-specific, 3D-designed TMJ reconstruction solution developed for managing severe temporomandibular joint disorders. It is intended for cases where conventional treatments fail, including joint degeneration, trauma, ankylosis, or post-tumor resection defects.

In which clinical indications is ReGraft™ TMJ recommended?

ReGraft™ TMJ is recommended for end-stage TMJ disorders, TMJ ankylosis, degenerative joint disease, failed previous TMJ surgeries, congenital deformities, and complex craniofacial reconstructions requiring precise joint restoration.

How does ReGraft™ TMJ improve surgical accuracy?

The system is based on patient-specific anatomical data derived from medical imaging, allowing precise pre-surgical planning and customization. This results in improved joint alignment, predictable occlusion, and reduced intraoperative guesswork.

Is ReGraft™ TMJ a customized solution for each patient?

Yes. ReGraft™ TMJ is a fully customized, patient-specific solution, designed according to the individual’s anatomy. This customization helps achieve better functional outcomes, improved symmetry, and optimal joint biomechanics.

How does ReGraft™ TMJ integrate into the clinical workflow?

ReGraft™ TMJ supports a digital clinical workflow, from imaging and virtual surgical planning to guided reconstruction. This streamlines coordination between surgeons, engineers, and manufacturing teams, reducing overall treatment time.

Does ReGraft™ TMJ reduce surgical and operative time?

Yes. Preoperative planning and precise customization significantly reduce intraoperative adjustments, leading to shorter surgical time, improved efficiency, and reduced anesthesia exposure for the patient.

What are the functional outcomes expected after ReGraft™ TMJ reconstruction?

Patients can expect improved jaw function, enhanced mouth opening, reduced pain, and restored mandibular movement, depending on clinical condition and postoperative rehabilitation. The solution is designed to support long-term functional stability.

Is ReGraft™ TMJ suitable for complex and revision cases?

Yes. ReGraft™ TMJ is particularly beneficial for complex, asymmetrical, and revision TMJ cases, where conventional stock solutions may not provide adequate fit or functional restoration.

Contact Us & Get details for