- Work Hours : Mon to Sat : 09:30- 18:30

Polyetheretherketone

(PEEK)

Overview

Polyetheretherketone (PEEK) is one of the well-known members of the Polyaryletherketone (PAEK) family of molecules, characterized by outstanding mechanical and chemical properties. Used widely in medicine for orthopaedic, trauma, dental, and spinal implants because of its dependability and safety record. Its proven track record in both moulding and 3D printing ensures that highly complex, robust, and safe medical devices can be developed to improve patient outcomes and further drive medical innovation.

Key Features

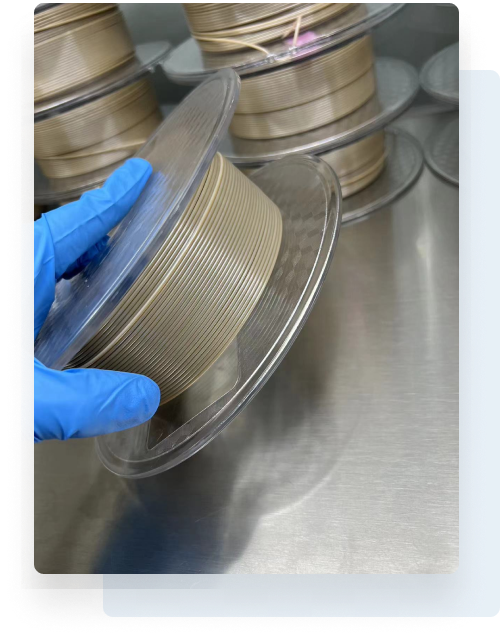

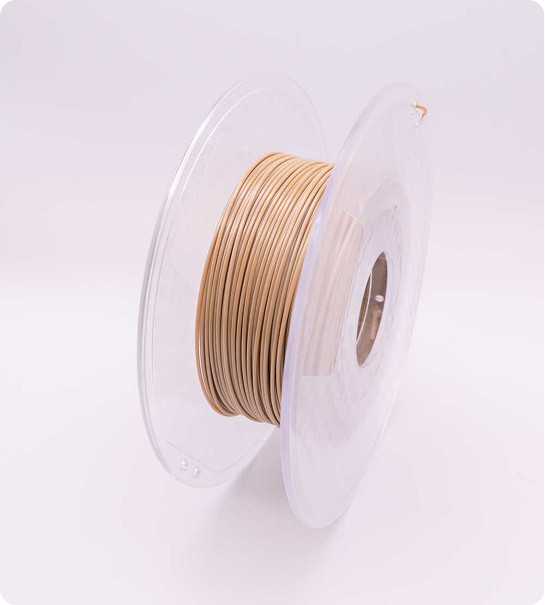

- Produced with medical-grade PEEK resin and precise engineered processes to ensure absolute quality.

- Meets stringent requirements for permanent implant use.

- 3D-printed PEEK components exhibit strength and durability on par with moulded parts.

Outstanding mechanical properties

Flexural Strength

151 MPa (ASTM D790)

Flexural Modulus

3.57 GPa (ASTM D790)

Excellent chemical resistance, especially to acids.

Thermal Properties of PEEK

Displays four main thermal transitions

Glass transition

143°C

Melt temperature

343°C

Flow temperature

400°C

Recrystallization

280–320°C

Biocompatibility and Material Safety

- Produced with Biocompatible: Proven non-toxic, non-mutagenic, non-carcinogenic, and non-immunogenic through extensive testing in animal models.medical-grade PEEK resin and precise engineered processes to ensure absolute quality.

- Comparable tissue response to controls (minimal reaction, no cell lysis or adverse effects).

- Extremely low rates of allergic or inflammatory reactions, with rare reported cases linked mainly to allergies, not the material itself.

- Suitable for permanent implants, including use near sensitive tissues such as the spinal cord and nerves.

3D Printing and Material Processability

- 3D printed objects achieve mechanical properties near or equal to those produced by traditional moulding.

- Extrusion controls are vital for ensuring filament diameter and print quality.

- Optimized algorithms and control systems enhance surface quality, dimensional accuracy, and stability of medical parts.

Chemical and Environmental Resistance

- Resistant to most chemicals, particularly acids, ensuring longevity and compatibility with various sterilisation agents and clinical environments.

- Maintains structure and function after repeated steam or gamma sterilisation cycles.

- Independent studies confirm PEEK’s elastic modulus and hardness are unchanged by typical sterilisation procedures.

Applications

- Orthopaedics & Spinal Surgery: PEEK has superior biomechanical compatibility with bone and soft tissues.Ideal for custom interbody cages, plates, and screws.

- Dental Implants: PEEK has high resistance to mechanical and fatigue stresses in the oral cavity.

- Craniofacial Reconstruction: Enables complex, fully customized designs for maxillofacial, cranial, and orbital defects. Demonstrated success in patient cases for both functional and cosmetic outcomes.

- Medical Device Components: Surgical instruments, microfluidic devices, body fluid containers, impellers, and more.

- Cardiac Implants: Innovative heart valve frames offer improved hydrodynamics and performance.

Certifications

USP Class VI and ISO 10993:

Assures compliance with international biocompatibility standards.

Sterilisation

- Gamma radiation and EtO sterilisation

- Maintains mechanical integrity and performance following processing.

- Robust heat resistance ensures safety in medical sterilisation and operational settings.

- Requires controlled processing temperatures to prevent unwanted crystallization and shrinkage.

FAQs

What is Polyetheretherketone PEEK and why is it used in medical implants?

Polyetheretherketone PEEK is a high-performance polymer known for strong mechanical and chemical properties. It’s widely used for orthopaedic, trauma, dental, and spinal implants due to its dependable safety record and suitability for complex 3D printed parts.

Why is PEEK used in medical implants?

PEEK is favored for medical implants because its mechanical stiffness closely mimics human bone, which reduces the risk of bone degradation caused by stress shielding.Its exceptional biocompatibility and chemical resistance ensure the material remains stable and non-toxic within the body, even when subjected to rigorous sterilization processes.Additionally, PEEK is radiolucent, allowing doctors to clearly monitor healing through X-rays and MRIs, while its versatility supports advanced 3D printing for patient-specific designs.

Where is PEEK commonly used in medical applications?

PEEK is used in areas such as orthopaedics, spine-related procedures, dental applications, and prosthetics, depending on clinical needs and approved workflows. Its use is guided by medical standards and clinician expertise.

Is PEEK 3D printing available in India?

PEEK 3D printing is available in India through specialized medical and industrial partners who support controlled workflows and quality requirements.

Is PEEK used for patient-specific implants?

PEEK is often considered for custom or patient-matched medical components. Its use depends on proper design validation, manufacturing quality, and clinical approval for each case.

How does Graft3D support medical PEEK workflows?

Graft3D supports medical PEEK workflows by providing technical expertise, application guidance, and training to help clinics and institutions adopt advanced medical manufacturing responsibly.