- Work Hours : Mon to Sat : 09:30- 18:30

Polymethyl Methacrylate

(PMMA)

Overview

Polymethyl Methacrylate (PMMA), often called acrylic, is a highly thermoplastic polymer synthesized from methyl methacrylate monomers. Owing to its lightweight nature, biocompatibility, high transparency, and excellent impact resistance, PMMA has become a preferred material for both industrial and medical applications. Applications of PMMA in healthcare range from intraocular lens to craniofacial surgical implants, making it a cornerstone in modern medical device innovation.

Mechanical Properties of PMMA

PMMA is a transparent, amorphous thermoplastic belonging to the acrylate family. Its molecular structure (C₅O₂H₈)n, can exist in isotactic, syndiotactic, or atactic forms.

- Transparency: Light transmission of 92–93%, higher than polycarbonate’s 86–89%.

- Glass Transition Temperature (Tg): 100–130 °C

- Density: 1.20 g/cm³

- Compressive Strength: 85–110 MPa

- Tensile Strength: 30–50 MPa

- Young’s Modulus: 2.4–3.3 GPa

- Refractive Index: 1.490

- Water Absorbency: 0.3%

Clinical Applications of PMMA

Dental Applications

- Prosthodontics: denture bases, artificial teeth, provisional crowns, retainers.

- Aesthetic advantages: Lightweight, natural looking, and cost effective compared to metallic alternatives.

- Cranial and maxillofacial surgery: Customized cranial implants for cranioplasty using CT based 3D models.

- 3D printed implants for conditions such as gingival smile correction.

Medical & Surgical Applications

- Orthopedic solutions: Biocompatible bone cement and prosthetic devices.

- Ophthalmology: Intraocular lenses and contact lenses.

- Cardiovascular devices: Blood pumps, dialyzers, and microfluidic systems.

- Cancer & radiotherapy research: Fabrication of PMMA dosimeters to study radiation dosage distribution.

Sterilization of PMMA Devices

Not all sterilization methods are compatible with PMMA due to its thermal properties. Avoid autoclaving (steam/dry heat), since exceeding Tg can deform or fracture the material. It resists many chemicals but may be vulnerable to esters, ketones, chlorinated solvents, and aromatic hydrocarbons due to its ester groups. By selecting sterilization carefully, PMMA devices maintain mechanical integrity and biocompatibility.

Recommended Methods

- Ethylene Oxide (EtO): Effective for heat-sensitive materials.

- Hydrogen Peroxide Gas Plasma (HPGP): Strong microbicidal action, non-toxic.

- Gamma Irradiation (γ): Can enhance flexural strength by modifying surface wettability.

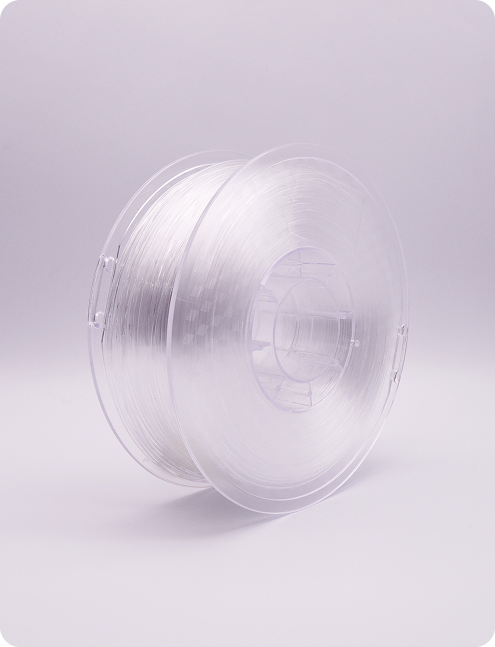

3D Printing with PMMA

Printing Parameters

- Extruder Temperature: 230–250 °C

- Bed Temperature: 60 °C

- Print Speed: ≤ 30 mm/s (PMMA performs best at low speeds)

- Safety Note: Printing releases gases. Always ensure proper ventilation during 3D printing.

- Fused Deposition Modelling (FDM): Optimizing layer height, raster angle, and infill density improves flexural strength.

- Direct PMMA Printing for Cranioplasty: Eliminates PLA molds, producing high-quality, patient-specific implants.

Certifications

ISO 10993 and USP Class VI-certified PMMA filaments ensure reproducibility, safety, and performance..

FAQs

What is medical-grade PMMA and where is it commonly used in clinical practice?

Medical-grade PMMA (Polymethyl Methacrylate) is a well-established biomaterial widely used in craniofacial reconstruction, maxillofacial surgery, neurosurgery, and facial contour restoration. It is preferred for patient-specific implants due to its biocompatibility, stability, and predictable clinical performance.

Is PMMA suitable for long-term craniofacial and facial implant applications?

Yes. PMMA has a long history of safe, long-term clinical use in cranial and facial reconstructions. When properly designed and implanted, it demonstrates excellent biological tolerance, minimal tissue reaction, and long-term dimensional stability.

What are the key mechanical properties of PMMA relevant to surgeons?

PMMA offers high compressive strength, good flexural resistance, and impact stability, making it suitable for both structural and contour-defining implants. These properties allow the implant to maintain anatomical accuracy under physiological loads without deformation.

Can PMMA be used for patient-specific, CT-based implant design?

Yes. PMMA is highly compatible with digital workflows, including CT/CBCT-based planning, CAD design, and 3D-manufactured implant fabrication. This enables accurate patient-specific implants, improving fit, symmetry, and surgical predictability.

How does PMMA compare with titanium and PEEK implants?

Compared to titanium, PMMA is lighter, radiolucent, and easier to modify intraoperatively. Compared to PEEK, PMMA offers a proven clinical track record, cost efficiency, and excellent surface finish, making it a practical option for many craniofacial and aesthetic reconstructions.

Is PMMA radiolucent and suitable for post-operative imaging?

Yes. PMMA is radiolucent, allowing clear visualization on CT and MRI scans without image artifacts. This supports accurate post-operative assessment, long-term follow-up, and complication monitoring.

What sterilization methods are compatible with PMMA implants?

PMMA implants are compatible with standard low-temperature sterilization methods such as ethylene oxide (EtO). These methods preserve the material’s structural integrity and dimensional accuracy while ensuring clinical safety.

How does PMMA contribute to reduced surgical time and improved outcomes?

By enabling pre-planned, anatomically precise implants, PMMA reduces intraoperative shaping, trial-and-error fitting, and overall surgical time. This leads to more predictable results, improved symmetry, and enhanced patient outcomes.