- Work Hours : Mon to Sat : 09:30- 18:30

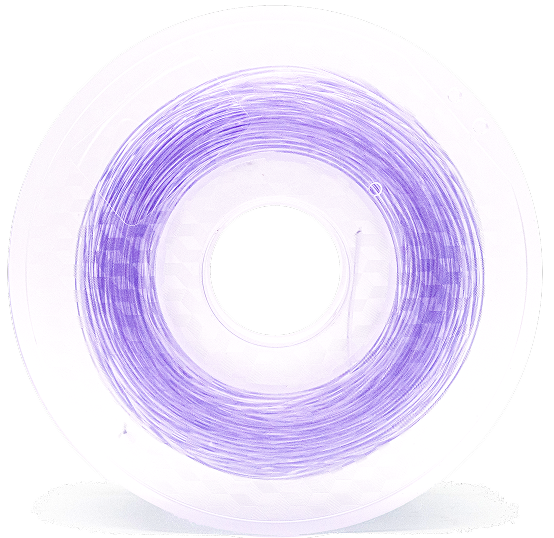

Polycarbonate (PC)

Overview

Medical Polycarbonate (PC) Filament is an advanced 3D printing material specifically engineered for the stringent standards of healthcare applications. Known for its biocompatibility, non-toxicity, and exceptional chemical resistance, it delivers superior impact resistance, rigidity, and drillability printed materials. Ideal for producing surgical guides, medical devices, and training models, Medical PC delivers both strength and reliability for critical healthcare environments.

Key Material Highlights

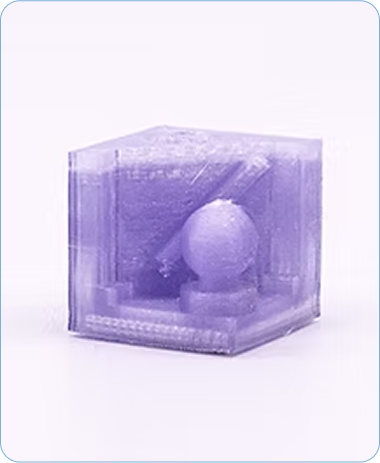

- High Optical Transparency: Polycarbonate is naturally transparent and can transmit over 90% of visible light, making it suitable for applications where clarity is essential.

- Exceptional Impact Resistance: Recognized for outstanding toughness, PC offers very high impact resistance and is virtually unbreakable under normal usage conditions.

- High Rigidity and Structural Strength: Medical PC filament exhibits high flexural strength and modulus, providing rigid, dimensionally stable parts suitable for precision medical devices.

- Excellent Chemical Resistance: Resistant to most acids and many chemicals found in laboratory and medical environments, ensuring durability and safety in challenging applications.

- Heat and UV Resistance: Maintains mechanical properties and optical clarity at elevated temperatures (up to 135–147°C) and offers good resistance to degradation from ultraviolet light.

Mechanical properties

- Tensile Strength: 52 MPa

- Elongation at Break: 21%

- Flexural Strength: 82 MPa

- Flexural Modulus: 2193 MPa (2.193 GPa)

- Heat Deflection Temperature (HDT @ 66 psi): 143.7 °C

- Young’s Modulus: Approximately 2.13 to 2.25 GPa

- Impact Strength: 26.9 to 76.8 J/m

Applications

Medical PC Filament is engineered for functional, durable, and critical-use medical parts, including:

- Surgical instruments and guides

- Training and demonstration models

- Laboratory and microfluidic devices

- Fluid-handling components (body fluid containers)

- Precision machine parts (pump impellers, stirrers)

- Customized prosthetic and biomedical devices

3D Printing and

Processability

Printing Technology Compatibility

Medical PC filament is primarily used with Fused Filament Fabrication (FFF) or Fused Deposition Modeling (FDM) 3D printers, which melt and extrude the filament layer by layer to create precise, functional parts.

Printing Temperature

Optimal extrusion temperatures for medical PC filament generally range between 260°C and 310°C, allowing the filament to melt properly while maintaining strength and layer adhesion. The printer bed temperature should be set around 90°C to 110°C to reduce warping and improve adhesion.

Print Speed

Due to its high melting point and viscosity, medical PC requires moderate print speeds, typically 30–60 mm/s, to ensure consistent extrusion and reduce print defects like stringing or warping.

Warpage and Shrinkage Control

Polycarbonate has a relatively high tendency to warp due to thermal contraction during cooling. Proper bed adhesion techniques such as using heated beds, build surfaces like PEI sheets or glass, and enclosure to maintain temperature stability are recommended.

Layer Adhesion and Strength

When printed using optimized parameters, PC filament provides excellent interlayer bonding, resulting in durable, tough parts.

Sterilisation

- PC medical filament is uniquely compatible with all major sterilization techniques, including autoclaving, due to its high thermal and dimensional stability.

- Unlike lower-temperature polymers, PC retains impact resistance and optical properties even after multiple sterilization cycles.

- The ability to use multiple sterilization methods allows flexible hospital workflows and broadens the use of PC parts for implants, surgical instruments, microfluidic devices, and other clinical applications.

Certifications

The biocompatible and non-toxic formulation, certified to USP

Class VI (USP 88)

Class VI (USP 88)

FAQs

What is polycarbonate used for in clinical workflows?

Medical-grade polycarbonate is used for surgical guides, drill guides, anatomical models, splints, and temporary prosthetic components where strength and precision are required.

Is polycarbonate safe for medical and surgical use?

Yes. Medical-grade polycarbonate is biocompatible and widely used in medical devices, making it suitable for temporary and intraoperative clinical applications.

Why choose polycarbonate over standard plastics or resins?

Polycarbonate offers superior impact resistance, higher strength, and better durability, reducing the risk of breakage during surgical handling.

Is polycarbonate accurate enough for surgical guides?

Yes. It provides excellent dimensional stability and low warpage, ensuring precise fit and reliable guidance during procedures.

Can polycarbonate withstand surgical handling and drilling forces?

Absolutely. Its high toughness and flexural strength allow it to tolerate drilling, fixation, and repeated handling without cracking.

Is polycarbonate compatible with sterilization protocols?

For PC filament for industrial and medical 3D prints, the page suggests extrusion around 260–310°C and bed temperature around 90–110°C, with moderate print speeds (30–60 mm/s) and enclosure/adhesion methods to reduce warping.