Surgical Guide Implant

Overview

Surgical Drill guide is a computer-guided surgical drill tool used for the placement of dental implants and other oral restorations. Its anatomical and surgical precision ensure an optimized fit of the implant onto the patient's jawbone, allowing the surgeon to place implants inside the bone with millimeter accuracy.

Benefits

Excellent fit with high accuracy with same-day implant

Designing surgical guides in less than an hour and conducting same-day implants.

Designing surgical guides in less than an hour and conducting same-day implants.

Flapless Insertion of Implants can take place using 3D printing.

Avoiding Bone Fracture in areas where the jaw is thin.

With the use of High-resolution 3D printing, we can precisely target the placement of implants during surgery. Drill sleeves may be inserted directly on the printed Guide, with an excellent fit

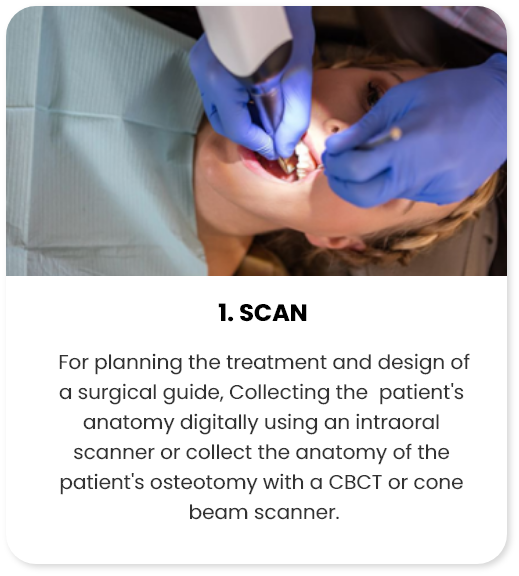

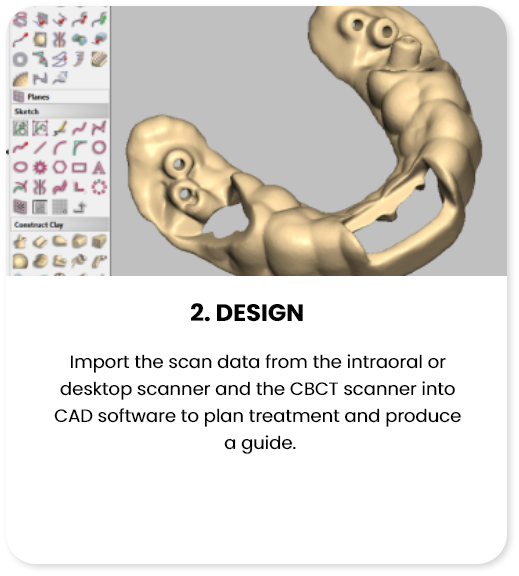

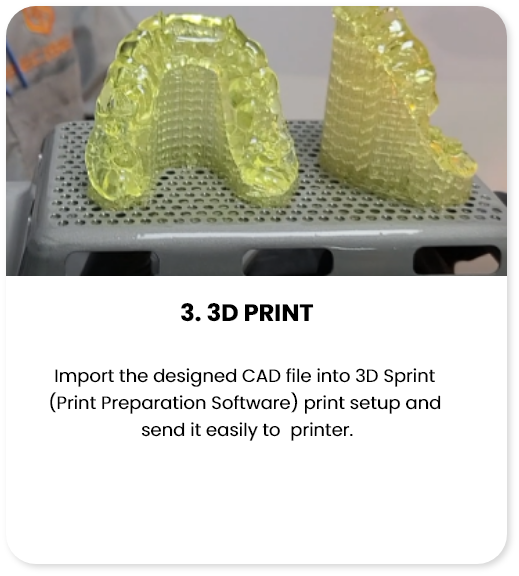

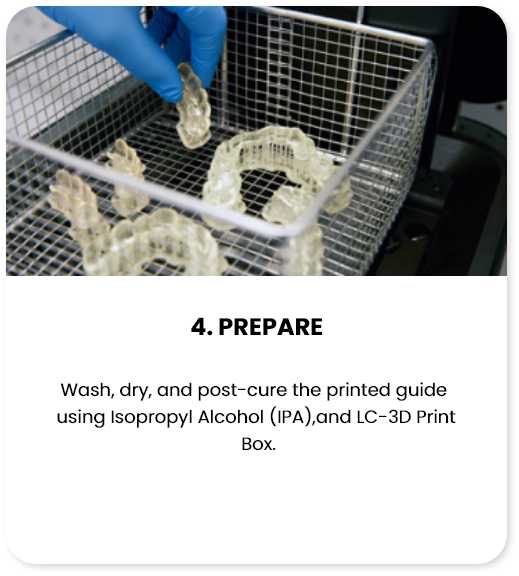

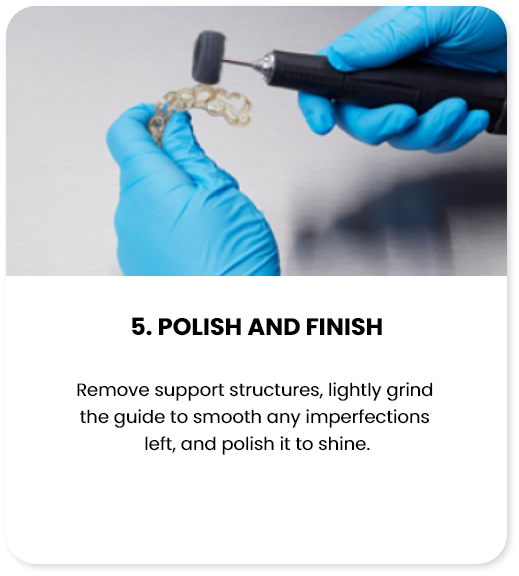

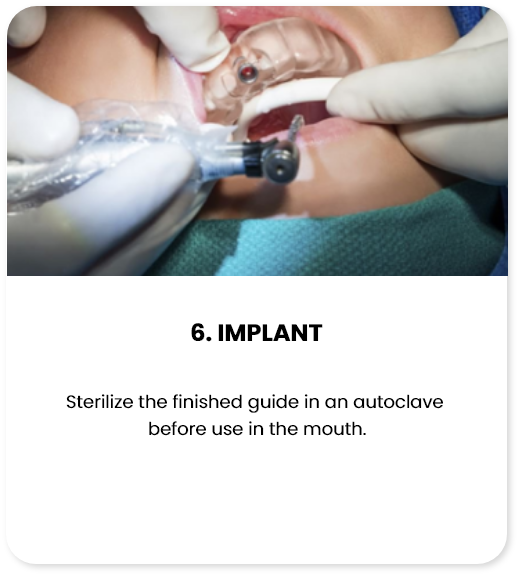

The Process

Testimonials

I have lost my nose While fighting Cancer, It broke me completely and I was depressed and stopped coming out of the home. Meeting Graft and Dr Sanketh Reddy was the best thing happened to me after suffering from cancer. The prosthesis matches my skin color precisely. I am very happy to go anywhere with much confidence.

- Kushal Gupta

I have met with an accident and lost my left ear and Loosing an ear at 21 had a huge mental toll. I Skipped college for a whole semester and I was no where near to meet new people. but with God’s Grace I have met Graft3D and they had the helped me with Artificial prosthetic Ears and that looks very real and that has made life as good as before.

- Arish Karthick

Our Blogs

Virtual Surgical Planning Assists With Full Face Transplant

Admin

June 28 2021

Geomagic Freeform Puts a Face To Missing Children

Admin

June 28 2021

Geomagic Phantom Haptic Devices Allow Surgeons to Practice Procedures Using Virtual Touch

Admin

June 28 2021

FAQs

For designing and manufacturing patient-specific implants we require the following information from surgeon’s side:

1. Patient’s radiological data (Usually CT)

2. Filled order form, including specifications for implant design, delivery, etc. After contacting us, the surgeon will get an order form that has to be filled, and CT scanning protocols with recommendations for scanning parameters.

Conversion of DICOM To STL > Virtually Planning and Designing Using Geomagic Freeform >3D Printing the Titanium implant > Post Operative OPG

Patient-specific implants are manufactured using the following technologies and materials: Additive manufacturing (3D printing) technology DMLS (Direct Metal Laser Sintering), material: medical titanium alloy Ti6Al4V ,FDM ( Fused Deposition Modeling) , Material : PEEK ( Poly-Ether-Ether-Ketone).

The lead time to design and manufacture a patient-specific implant or surgical guide depends on the complexity of a clinical case and the surgeon’s requirements for the device. Typically, the delivery terms (after the surgeon approves the final design) are approximately 2 weeks for implants, and 1-2 weeks for surgical guides.

There is a provision in our Web Page, where you can fill the Details of the patient and upload their DICOM files. ( Please Give the Link Of < Get Quote > )