- Work Hours : Mon to Sat : 09:30- 18:30

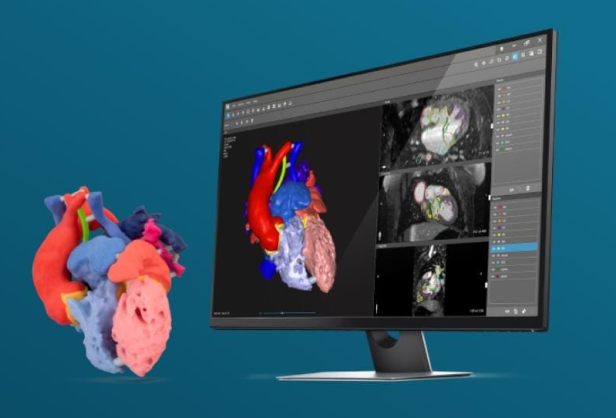

Geomagic Freeform with Haptic

Comprehensive Medical Design Software For Custom Medical Devices

Graft3D Healthcare

Medical 3D Printing Solution Provider

We Design and Develop Custom Healthcare 3D printed products, Healthcare 3D printing packages and Healthcare 3D services for hospitals and surgeons.

Call us now

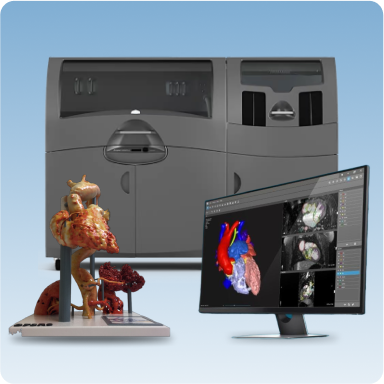

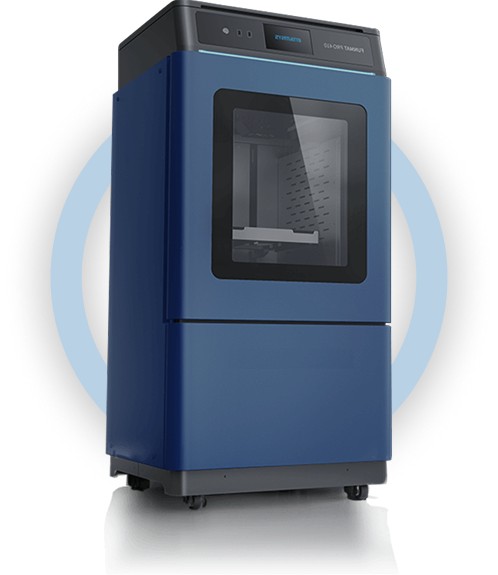

Medical 3D Printer

Funmat Pro 410

Self-Developed FFF (Fused Filament Fabrication) Core Technologies

About Us

Graft 3D is a healthcare solutions provider that partners with global technology firms.

To deliver Medical 3D printing-based products tailored for hospitals, surgeons, and patients. Leveraging the expertise of our in-house doctors and engineers, we also design, develop, and promote futuristic Medical 3D printing and scanning-based products. We are committed to advancing medical 3D Printing technology, improving patient outcomes, and driving the future of healthcare through cutting-edge 3D printing technologies. Discover how we’re shaping the future of healthcare at Graft3D Healthcare.

250+

Parts Medical 3D printed

200+

Happy Healthcare Customers

30+

Medical 3D Software Installed

10+

Medical 3D Printing Applications Developed

Book A Free Online Demo

Witness how we design Custom Medical Device 3D Printed Products using Geomagic Freeform and D2P.

Thank you for showing interest in our medical 3D printed product design process, which primarily uses medical image processing and bio-cad medical modeling.

You can pick up the preferred demo timing that suits your schedule. The initial demo will be 30 mins to 1 hour, which will take place in our Zoom virtual meeting space accessible through our website.

Kindly inform us of your specific interests and applications to make the demo as informative as possible. Whether focusing on CMF implant design, surgical cutting or drill guide development, artificial limbs and custom facial prosthetics, we will tailor the demo to address your specific needs.

Following the demo, we’ll provide a complimentary benchmark session to showcase how our advanced software, including D2P and Freeform, can enhance your medical 3D printing endeavors.

Thank you for considering Team Graft3D. We look forward to the opportunity to assist you in achieving your goals and advancing your medical 3D printing projects.

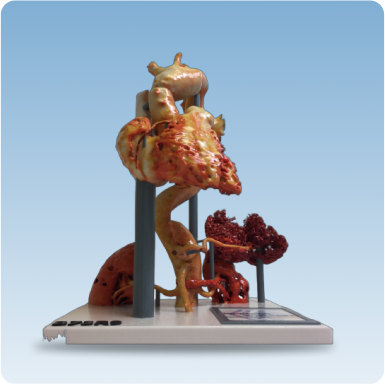

Our 3D Printed Products

Our 3D Packages

Services

Exclusive Online Platform For

Healthcare 3D Services

- DICOM to 3D conversion service

- Custom Medical Design Service

- Medical 3D Printing

Do you have the medical scans in hand and are looking for a reliable vendor to convert medical images, such as CT, CBCT or MRI scans, into high-quality 3D models? Graft3D can help you with high-quality image segmentation services using advanced Dicom to 3D conversion software. Medical professionals can use our segmented models for 3D printing, visualization, pre-surgical planning, and patient education. Our 3D models can also be used as a source to design Custom Implants or Medical Devices in any medical design software.

Graft3D can assist with custom medical device design of life-saving implants, surgical cutting and drill guides, or anything tailor-made to the patient’s unique requirement. Our in-house team consists of doctors, Bio-CAD model specialists, and experienced engineers who collaborate closely with you to ensure that every design aspect and end product seamlessly aligns with your patient’s unique anatomy and medical condition while ensuring the manufacturability or 3D printability.

We offer comprehensive end-to-end medical 3D printing services with appropriate certification for 3D printing materials, processes, and 3D printers for global export. Our medical printing services are exclusively for custom implants, surgical guides or artificial human organs. We tailor our approach to the patient’s unique requirements and perfect fit.

Healthcare 3D Printing Service In India (Online Platform )

Upload DICOM Image OR 3D

scan

Convert your DICOM image to

3D files

Consult Our Doctors & Bio CAD

Modellers To Design Patient

Specific Medical Devices

Get Healthcare 3D Printed

Parts At Your Doorstep

Our Valuable Customers

Our Clients

Testimonials

Our recent Healthcare 3D service projects, such as Medical 3D image segmentation and Bio CAD modeling for 3D printing, serve as a testament to our proficiency and dedication in providing outstanding 3D services. Whether you require image segmentation, bio CAD modeling, or comprehensive medical 3D printing solutions, we have all your needs covered.

Doctor

We use advanced software to preprocess images, such as noise reduction or contrast enhancement. This step ensures the input image is of the best quality for segmentation.

Doctor

We use advanced software to preprocess images, such as noise reduction or contrast enhancement. This step ensures the input image is of the best quality for segmentation.

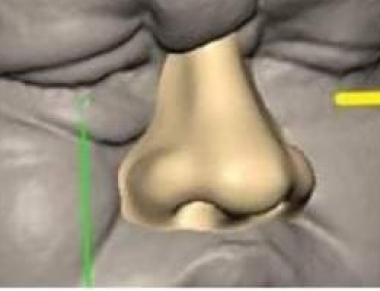

OralCase Study on replacing Cancer infected Nose with Artificial Nose Prosthesis

June 21, 2021

OralCase Study on replacing Cancer infected Nose with Artificial Nose Prosthesis

June 21, 2021

OralCase Study on replacing Cancer infected Nose with Artificial Nose Prosthesis

June 21, 2021

FAQs

What should I look for in a medical 3D printing company?

A medical 3D printing company should offer end-to-end capability: medical image processing, bio-CAD modeling, quality control, and reliable printing options. Prioritize healthcare focus, proven hospital workflows, and support for surgeons from planning through final delivery.

How does healthcare 3D printing India support better surgical planning?

Healthcare 3D printing India helps clinicians translate scans into true-size anatomical models for pre-op planning, training, and patient education. A structured digital workflow reduces guesswork, improves team alignment, and can sharpen operating-room decisions for complex cases.

How are patient-specific implants India designed from medical scans?

Patient-specific implants India typically start with CT data, followed by segmentation, bio-CAD design, and validation with surgeons before manufacturing. A controlled process helps match anatomy, support fixation needs, and align the design with the planned surgical approach.

What is anatomical 3D model printing and who benefits most?

Anatomical 3D model printing produces physical replicas of patient anatomy for surgical planning, training, simulation, and patient communication. Orthopaedics, maxillofacial, neurosurgery, and cardiology teams benefit because complex structures become easier to study and explain.

Can 3D prosthetics India be customized for comfort and function?

3D prosthetics India can be customized using body scans and CAD design to match patient geometry, improving fit, comfort, and repeatability. Digital workflows also standardize fabrication and documentation, making it easier to reproduce, audit, or update devices later.

What are custom medical 3D printed solutions typically used for?

Custom medical 3D printed solutions are commonly used for surgical aids, patient-specific models, orthotic and prosthetic devices, and planning tools. Success depends on matching materials and process to clinical needs, then validating dimensions before patient use.

How does a CT/MRI to 3D model service work from DICOM files?

A CT/MRI to 3D model service starts by converting DICOM scans into segmented anatomy, then generating a printable 3D file for review. After clinician approval, the model can be printed at true scale for planning, training, or mock-up surgery.

How does 3D printing for surgeons improve outcomes and efficiency?

3D printing for surgeons improves visualization of anatomy, supports rehearsal of complex steps, and helps select implants or approaches with confidence. When models are true-size and delivered quickly, teams can plan precisely and communicate better in theatre.

How do I choose an anatomical model maker India for my hospital?

An anatomical model maker India should provide accurate scan-to-model conversion, material options for coloured or bone-like realism, and dependable lead times. Ask about clinical review checkpoints, case experience, and quality documentation for repeatable orders.

What are bio-CAD modeling services and why are they important?

Bio-CAD modeling services turn medical imaging into editable 3D designs for planning, surgical guides, and custom devices. Strong modeling reduces errors, supports repeatability, and enables surgeon feedback before printing critical for predictable timelines and consistent results.

What is a DICOM to STL conversion service and what files are needed?

A DICOM to STL conversion service transforms CT or MRI DICOM data into a printable 3D STL model using segmentation and cleanup. You typically share the DICOM folder and clinical intent, then review the 3D preview before production.